Identification and master data of raw materials

Common model for the identification and master data of raw materials

Building interoperable traceability in the food chain requires that raw materials are also reliably identified and related information is shared in a uniform format. This is the only way for information to flow transparently and interoperably throughout the chain, all the way from the field to the consumer. A proposal and a common view on how raw materials can be identified and what information needs to be linked to raw materials from the perspective of traceability and regulation was created in the development project Data model of raw material master data, part of the Interoperable Traceability program.

GTIN as a basis for identification

The GTIN (Global Trade Item Number) plays a decisive role in the identification of raw materials. It is an internationally recognised identifier that is already widely used in consumer products. The application of the GTIN to raw materials also enables the unique identification of products regardless of the supplier or the country in which the raw material is produced. This prevents a duplication of identifiers and ensures that the exchange of information between different systems and operators runs smoothly at both national and international levels. GTIN thus provides a sustainable basis for the traceability of raw materials.

Master data model as a basis for data exchange

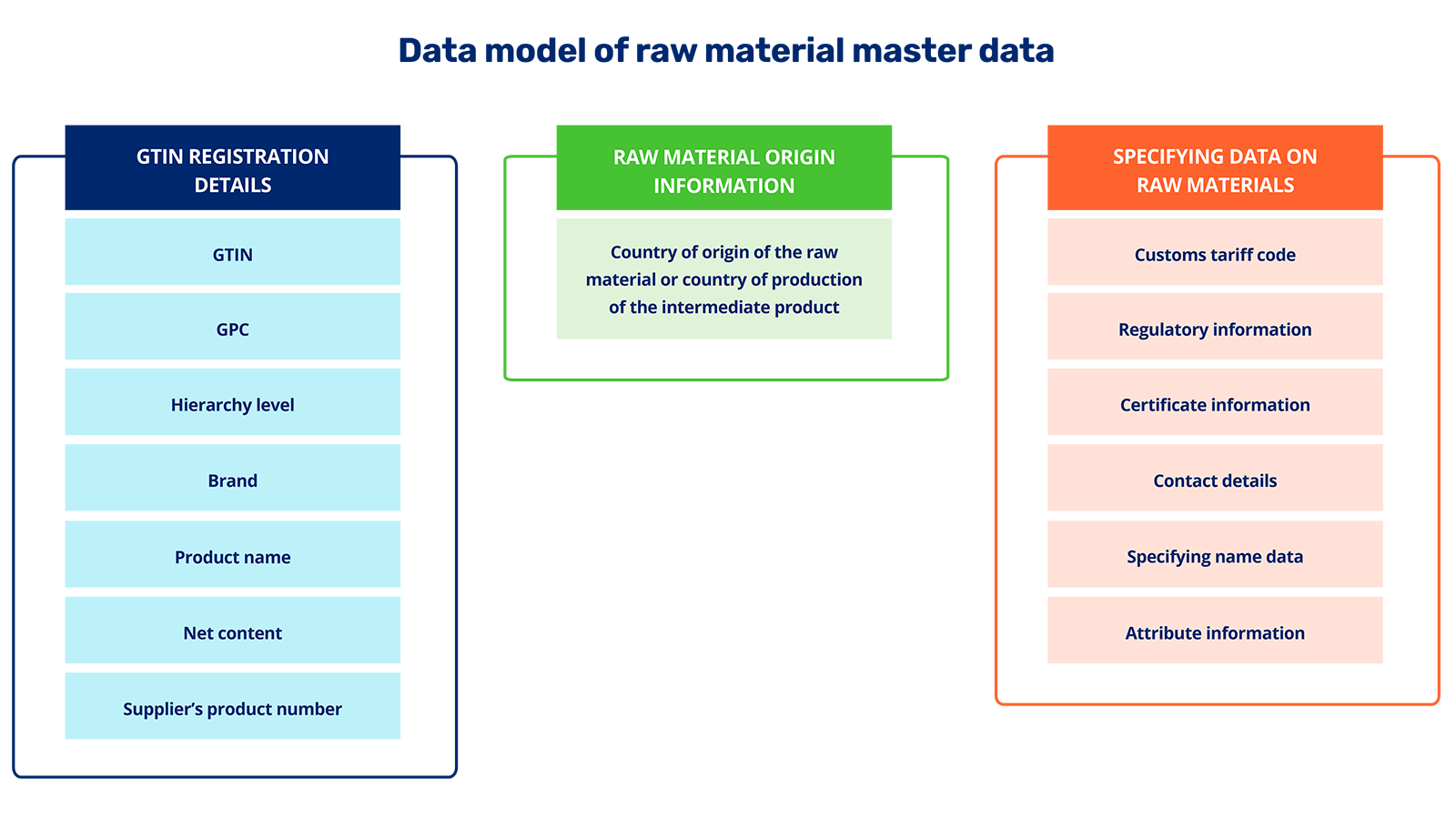

For interoperable traceability, however, an identifier alone is not enough. Therefore, alongside the GTIN, a master data model is needed, which specifies the minimum data content to be transported for all raw materials in the chain. The data included in the model is permanent master data that does not change from batch to batch and is carried along with the raw material throughout the chain. Common information includes, for example, the country of origin, certificates and regulatory information as well as attribute information, such as organic information or suitability for special diets. Information about allergens has also been identified as a critical part of the model, as it must pass unchanged through the entire value chain.

The core idea of the data model is that it provides a common minimum data content for all raw materials, but, at the same time, it is also flexible to meet the needs of different product groups. The model is built so that it allows you to refine, expand and respond to special cases without losing interoperability.

The basis for interoperable traceability of the food chain

When the GTIN and the data model are combined, the basis for interoperable traceability is created. The GTIN enables the unambiguous identification of a raw material, and the associated master data model ensures that consistent and comprehensive master data about the raw material is available, for example, already before shipments. Thanks to this foundation, batch information and events generated along the raw material journey—such as shipments, receipts and processing stages —can be reliably linked to the correct raw material and its master data.

As a whole, the solution reduces the fragmentation of information, enables a more efficient and largely automated information exchange and strengthens the transparency of the entire food chain. This supports companies in meeting regulatory requirements, managing risks and verifying sustainability claims—while providing a competitive advantage in both the domestic and international markets.