Fazer, S Group, KLINGER Finland and GS1 jointly test 2D code that brings intelligence to consumer packaging

The QR-like 2D code on the back of the bag is a new global marking method that allows more detailed data to be transmitted via packaging. The GS1 2D code includes a unique product number, the GTIN code, which the checkout system reads in the same way as an EAN barcode. Compared to the traditional EAN code, the 2D code contains a link to consumer-facing online content as well as variable batch-specific information for the supply chain, such as best before dates and production batch details.

– GS1 2D code offers several benefits: it enables more detailed product information sharing, improves traceability, and provides consumers with easy access to additional product details. The code also streamlines information flow between retailers and manufacturers and opens new opportunities, for example in food waste reduction and enhancing customer experience, says Katja Santala, Director, Packaging Development & Technology at Fazer.

In the long term, 2D codes may replace EAN barcodes

The aim of the joint pilot is to explore the prerequisites for implementing GS1 2D codes, such as data content, system integration, and packaging technology requirements for marking and quality assurance solutions.

– Regulation related to product traceability is constantly increasing, and dynamic 2D barcodes are one solution to make this information available to both retailers and consumers in the future. Although we are still at an early stage, this pilot allows us to assess the concrete benefits of 2D barcodes in the value chain and the process changes required for their future use. We look forward to the results, says Mikko Hänninen, Development Director at S Group’s grocery trade.

– It is great that Finland is now carrying out the first practical trials of dynamic GS1 2D codes. These trials drive development toward a smarter and more transparent supply chain. GS1 2D code is based on a global standard, which ensures that the information flows smoothly and interoperably between different actors – also internationally. When batch data moves through the chain, product safety and responsibility can be strengthened by linking, for example, more detailed information about product origin,” says Standards and Compliance Lead Kimmo Keravuori from GS1 Finland.

For consumers, the 2D code appears as a QR code that can be scanned with a smartphone camera. In this pilot, the code directs consumers to the Remix 30th Anniversary campaign page to participate in a prize draw. In the future, the code could, for example, provide access to sustainability information or make it easier to submit product feedback.

Collaboration makes the pilot possible

– As a manufacturer, Fazer does not benefit from piloting the dynamic code alone. We need retail as a partner to understand how and where this new standard could improve information sharing, Santala explains.

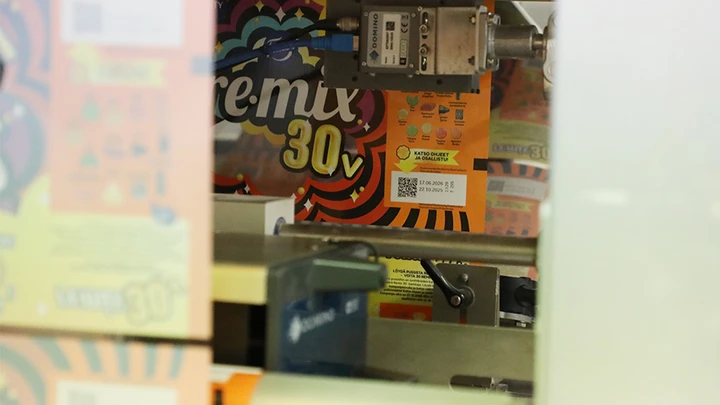

Fazer Remix is produced at Fazer’s confectionery factory in Lappeenranta. Each anniversary package receives its own batch-specific GS1 2D code, printed directly on the packaging line using a solution implemented by KLINGER Finland, unlike traditional QR codes added to printed packaging materials.

– In this pilot project, our role was to deliver a reliable and cost-effective marking solution that combines product marking and automatic quality control. In cooperation with our principal Domino Printing Sciences, we designed and implemented a solution that uses next-generation foil printing technology and Domino’s R-series camera inspection. With camera inspection, we ensure that no product leaves the packaging line without the correct marking, says Jari-Pekka Eskelinen from KLINGER Finland.

Pilot: 2D code brings intelligence to the Remix 30th Anniversary bag

- The 2D code contains the GTIN product number, a web link, and, if needed, other standardized information. It streamlines information sharing across the entire supply chain.

- The code can include a wealth of consumer-relevant information that can be updated and changed quickly.

- In the pilot, companies actively discuss the benefits and potential use cases of the code.

- In the long term, 2D codes could replace EAN barcodes.

- The pilot does not aim for immediate implementation but serves as an important learning platform for all parties.

Additional information